Due to its optical tracking technology, TrackScan-Sharp can precisely measure parts without having to stick reference targets. Its large tracking volume allows users to measure multiple parts at the same time, thus significantly improving operations efficiency.

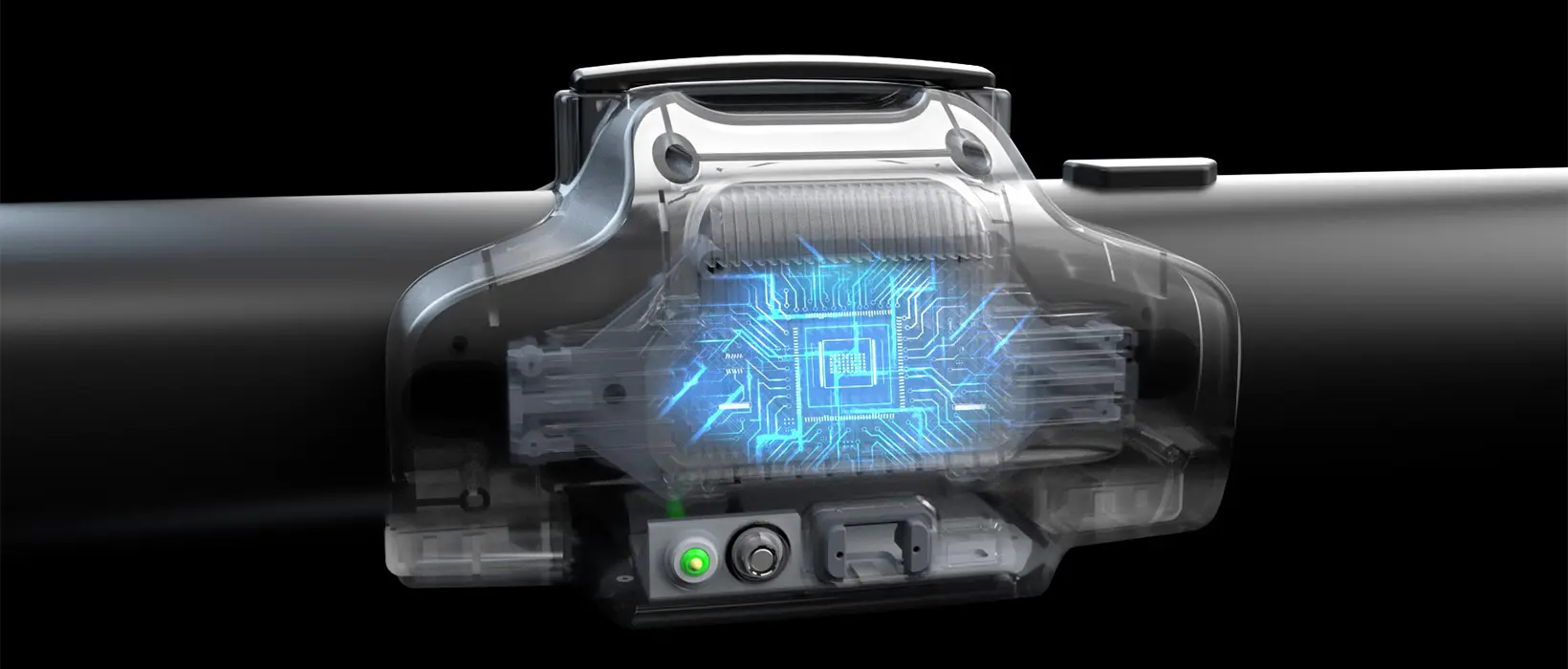

The 3D scanning system can transfer data both with and without wires. With wired mode, the system can send data over a long distance in line with industrial measurement standards. Optional wireless mode support applications, in different working conditions, which is convenient due to its plug-and-play operations. It can be set up quickly and operated flexibly to cater to various environmental conditions, ensuring efficient measurements.