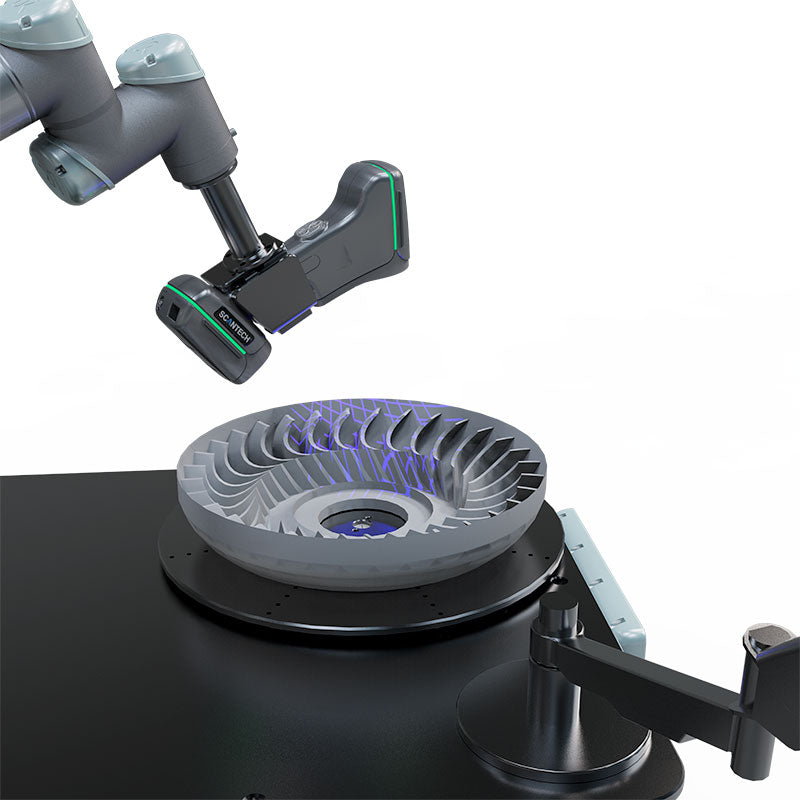

Automatic Whole-process Inspection

Without human involvement, AutoScan-K is an automated 3d scanner that can automatically conduct batch 3D scanning and inspection for data comparison, and generate inspection reports, after scanning routes and measurement process are set for different products.

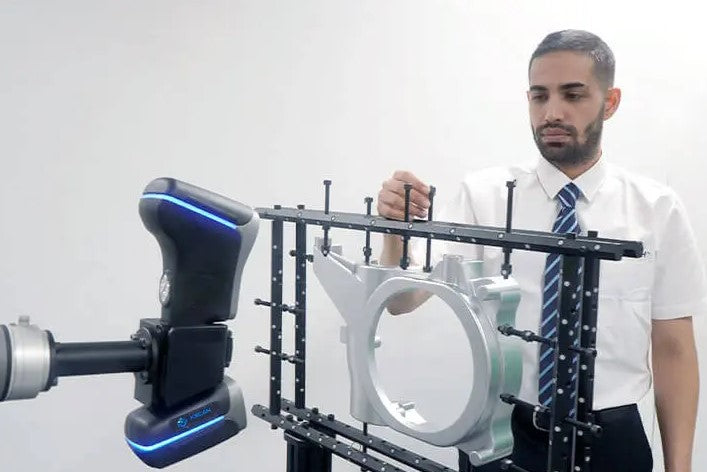

Personalized Operation

Multiple measurement modes are offered depending on the characteristics of different workpieces. To meet different inspection requirements, the workpieces can be clamped from multiple angles to set inspection routes.

Safe and Reliable NDT

Based on automated optical measurement technology, the AutoScan-K automated 3d system truly achieves non-contact and non-destructive intelligent testing, which is safe, reliable, and applicable in different workshop environment. Its industrial intelligent rotary tables make efficient and blind-angle-free inspection possible

Precise and Effective Measurement

AutoScan-K can inspect workpieces with different sizes, weights and pieces made from different materials. It can generate as much as 45 laser lines for high density data scanning, with the speed of up to 1,650,000 per second. It enables precise 3D inspection in harsh industrial environment with resolution up to 0.010 mm and volume accuracy up to 0.030 mm/m.

Secondary Development

The secondary development allows operators to control the system by calling the SDK interface.