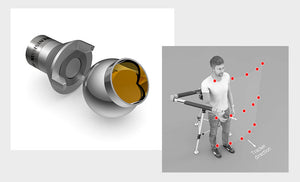

Simple and fast

positioning process

- 1 . Fit the Track Ace interface on the Ace arm. The Track Ace interface uses Renishaw attachment to be perfectly repeatable.

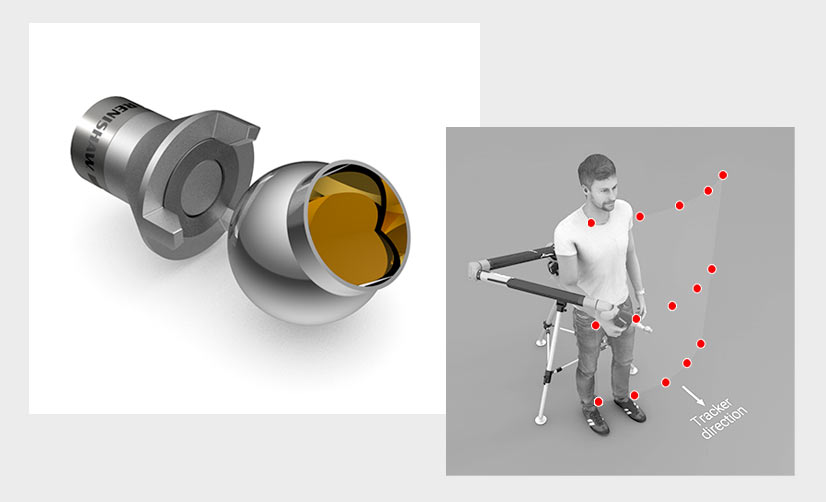

- 2 . Place the SMR sphere inside the interface.

- 3 . Facing the tracker, take a grid of 15 points in space with the arm.

Total positioning time is less than a minute.

No shadow zones

After the laser tracker has determined the position of the measuring arm, the arm can work independently of the tracker. When the operator is using the arm to measure, he can move freely, like all the workers in the area, without the risk of breaking the connection between arm and laser tracker. The continuity of the work rate in the workshop is thus maintained.

Independent systems for a faster return on investments

Use of the tracker alone (with SMR probing)

- Long range 3D measurement

- Machine alignment

Use of the ACE measuring arm alone

- Measuring inside small spaces or vehicles

- Measuring smaller parts, from 1cm to 4m (depending on the arm size)

- Scanning high requirements parts

Tracker main characteristics

- Distance range: 50m or 80m

- SMR probing

- Wireless

- Battery operation: 10 hours

- Environmental compensation

- Short preheating

- Autolock, rapid recapture of a lost laser beam

- Integrated controler