Artec 3D

Scantech 3D

Kreon 3D

Automated Solutions

Additional Scanners

collaborative robots

Geomagic Software

Artec 3D

Artec 3D

QuickSurface

QuickSurface

Verisurf

3DFlow

3DFlow

Raise 3D

Makeit

Accessories

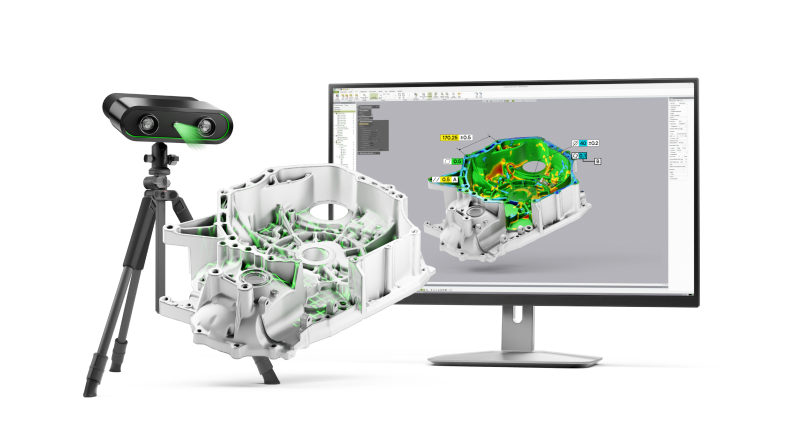

We’re making inspection simpler. Capture and automate the processing of data from 3D scanners and other devices. Measure, understand, and communicate inspection results with next to no human interaction.

Speak to Sales or (562) 912-3544

Why Geomagic Control X?

Easy to learn. Anyone can get results with little or no training.

Fast and easy to use. Handle huge data sets quickly and easily with scan-native algorithms built on a CAD kernel.

Complete solution. Get all the tools you need for professional-level inspection.

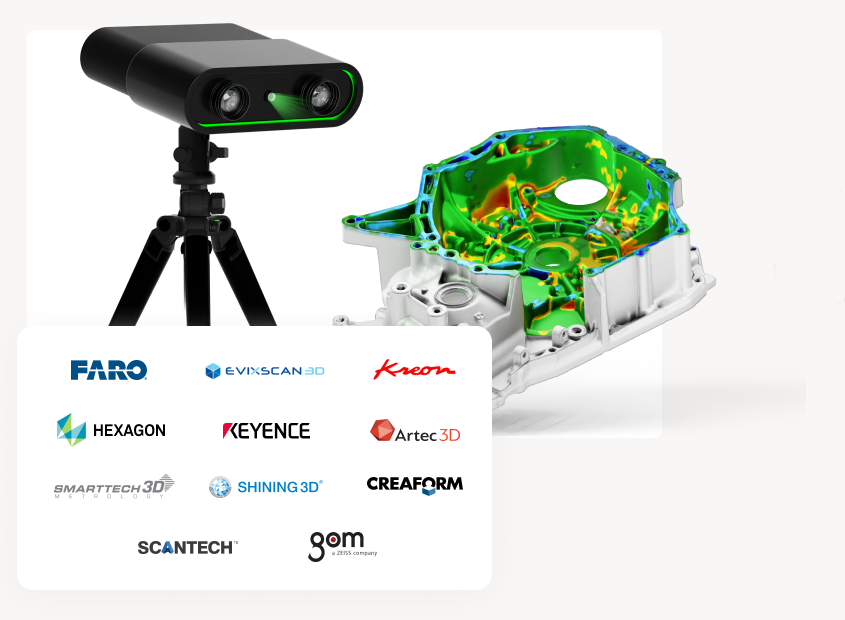

Compatible with all 3D scanners. Work with any 3D scanner or PCMM arm.

What is Geomagic Control X?

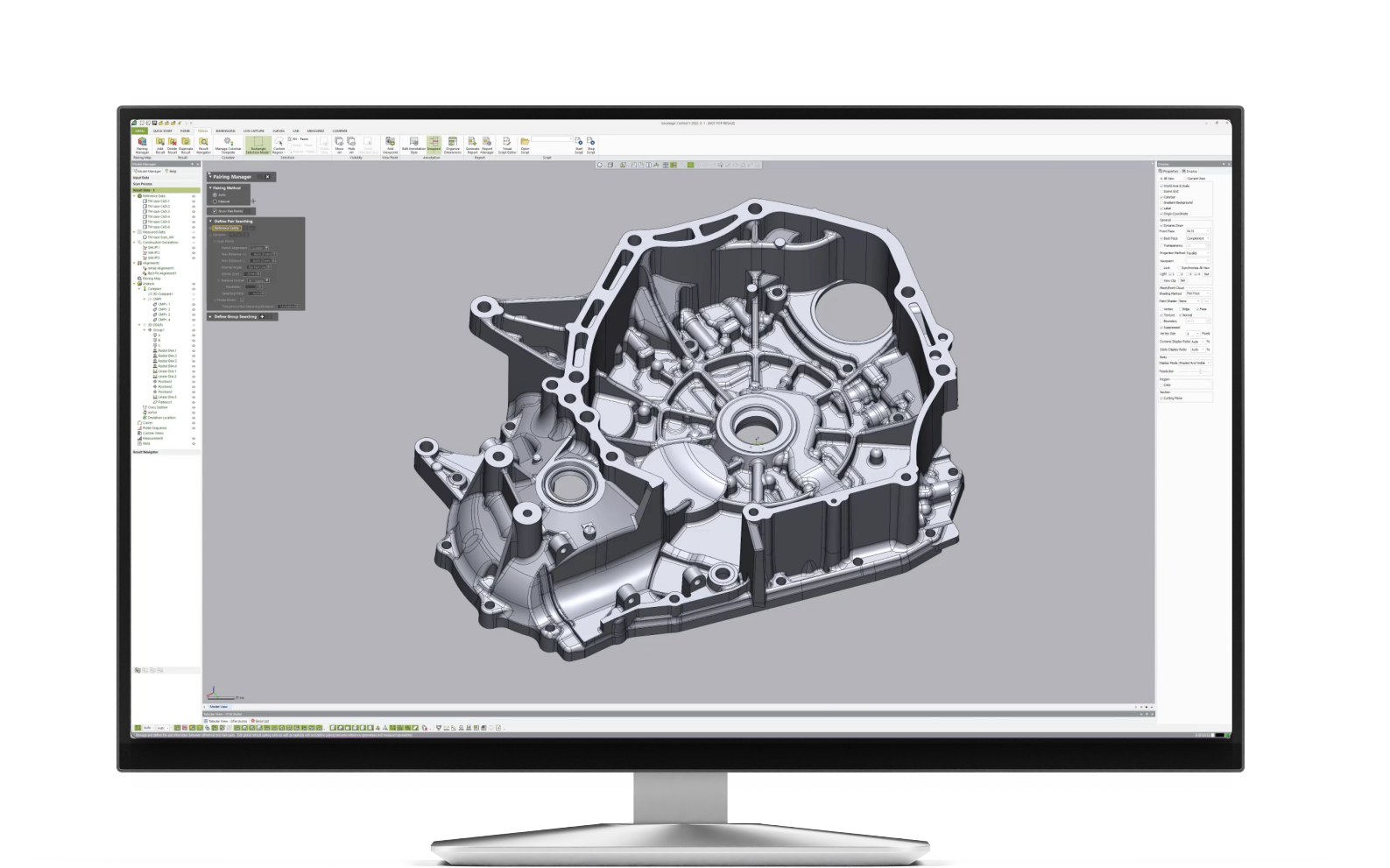

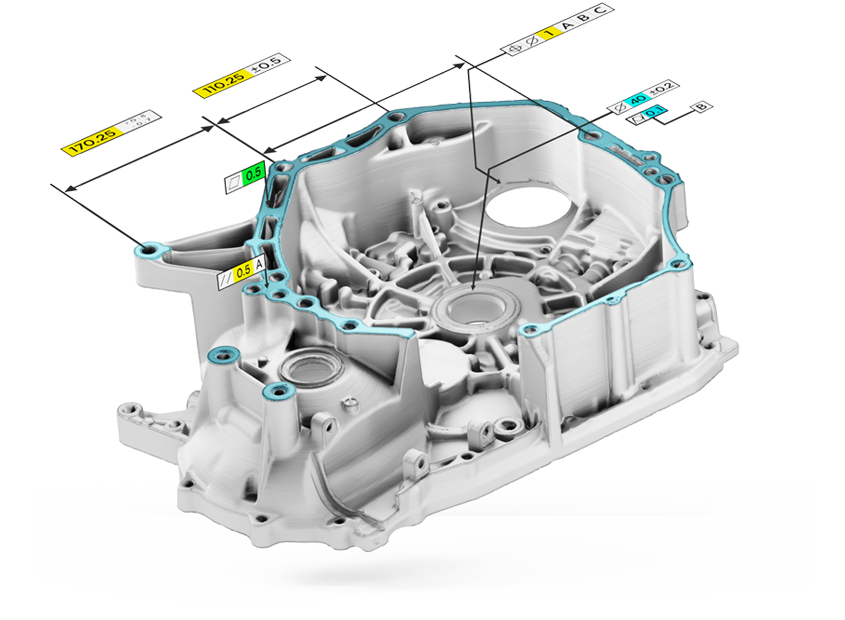

Geomagic® Control X™ is a professional 3D quality control and dimensional inspection software that lets you capture and process the data from 3D scanners and other portable devices to measure, understand, and communicate inspection results to ensure quality everywhere.

Inspection isn’t just for metrology specialists. Geomagic Control X empowers everyone to measure, understand, and make decisions about their parts faster, more often, and more completely—from anywhere.

Ensure quality everywhere. Bring the power of 3D scan-based inspection to more people in more places with software that makes it easy to both capture and interpret scan data.

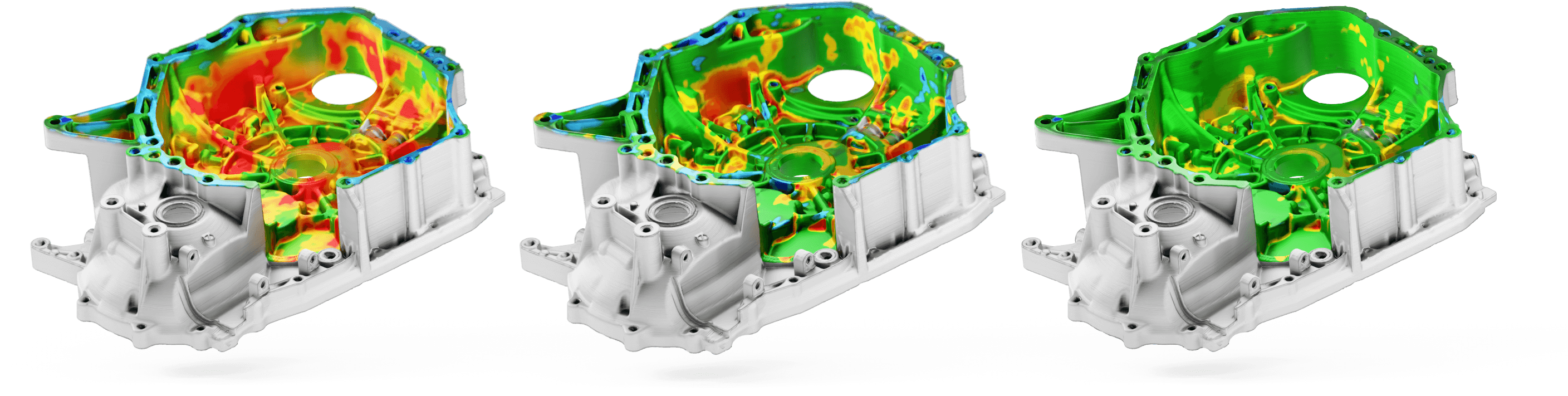

Gain deeper insights beyond pass/fail. Scan parts to capture more information and leverage rich data to understand why parts are in or out of tolerance.

Optimize manufacturing processes. Recognize and address issues faster with insights gained from comparing scanned parts to CAD models or golden parts.

Improve inspection agility by integrating with most scanners and PCMMs on the market.

Intuitive UI makes complex metrology tasks more accessible.

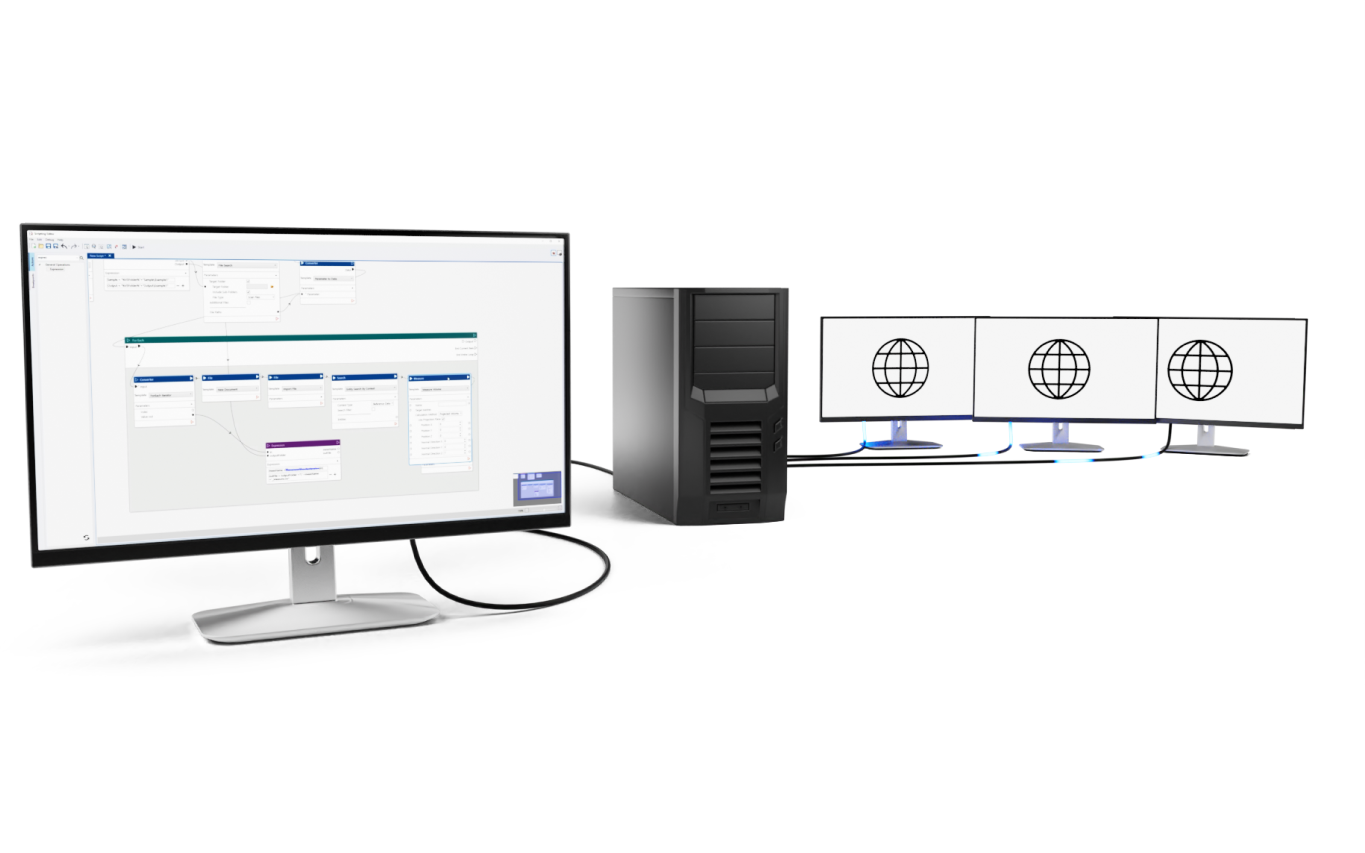

Prevent false part scrappage by automating repetitive tasks with straightforward visual scripting functionality.

Reduce costly downtime by measuring right first time, every time.

Recreate blades and blisks with efficient turbine blade averaging workflows.

Fast and accurate volumetric reporting, perfect for costing and planning additive production of heat exchangers.

Automate a set inspection routine, even when the reference geometry changes from patient to patient.

Accurately report out surface area data for electro-plating components.

Wear analysis and replacement prediction of important components such as ball mills.

Measurement of deformation of material exposed to external events such as explosions or radiation.

Bring the power of 3D scan-based inspection to more people in more places.

Drive your 3D scanner or PCMM directly inside Control X or work with data from any device.

Customize and maximize inspection throughput with Visual Scripting and Automation Server capabilities.

Quickly and intuitively gather profile measurements, including twist analysis, for turbines, blisks, blades and more.