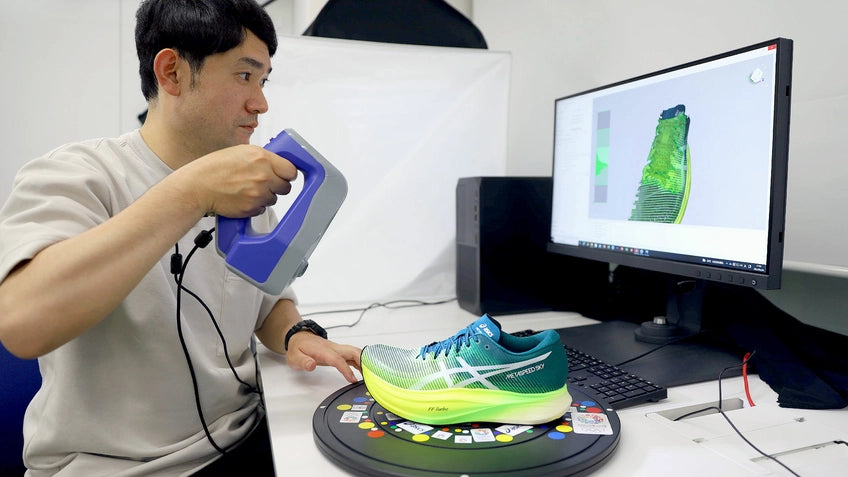

ASICS recently integrated cutting-edge 3D scanning and photogrammetry technologies to enhance their footwear design and quality control processes. Using the Artec Space Spider, a highly accurate blue-light scanner, ASICS captures both the external and internal details of its footwear with exceptional precision and vivid textures. This high-resolution scanning is paired with photogrammetry, leveraging DSLR cameras for enhanced color accuracy and texture mapping.

The workflow begins with scanning a shoe from multiple angles using the Space Spider, followed by detailed photography for texture mapping in Artec Studio. The resulting 3D models are used for various applications, including marketing and quality control. For precise inspections, the data is integrated into Geomagic Control X software, enabling swift and accurate comparisons between scanned models and CAD data. This streamlined approach minimizes manual errors and automates inspections, saving time while providing highly reliable results.

ASICS plans to expand this technology to reverse engineering materials and improving their product lines further, ensuring continued innovation and customer satisfaction. For more details, visit the full case study on Artec 3D’s website.

ASICS plans to expand this technology to reverse engineering materials and improving their product lines further, ensuring continued innovation and customer satisfaction. For more details, visit the full case study on Artec 3D’s website.