Artec 3D scanned a massive 19th-century gas engine in Luxembourg, marking one of the largest scanning projects they've undertaken. The engine, too large to move, was scanned on-site using Artec’s powerful, portable scanners. This complex process captured precise details for digital preservation and future restoration needs, creating a highly detailed 3D model of the engine. This case illustrates how advanced 3D scanning technology can preserve industrial heritage by digitizing even the largest and most intricate objects.

Gas Engine #11

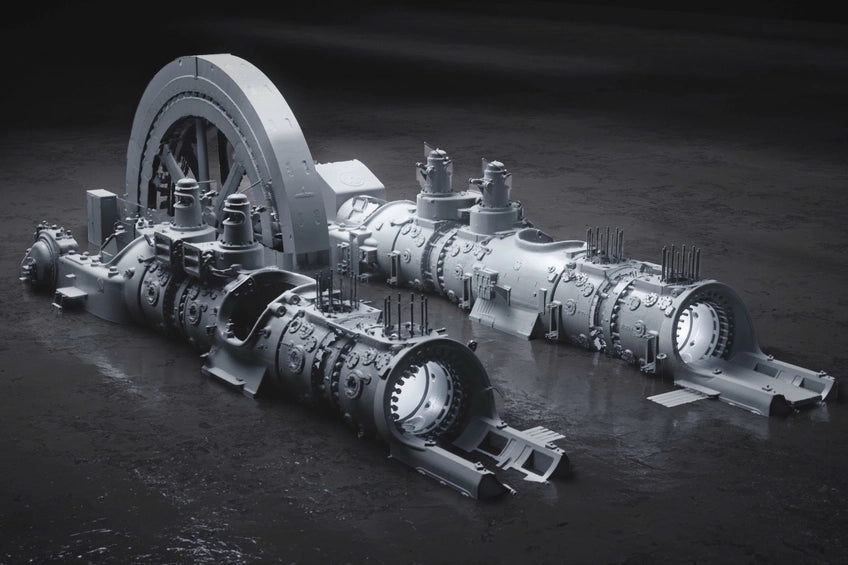

Built in 1938 by Ehrhardt & Sehmer, the Groussgasmaschinn is the largest gas engine ever built

Built in 1938 by German manufacturing company Ehrhardt & Sehmer by order of a Franco-Belgian consortium called “Hauts-fourneaux et Aciéries de Differdange, St-Ingbert & Rumelange” (HADIR), the Groussgasmaschinn is so large it could contain an entire tennis court, and then some. It is 26 meters long, 10.5 meters wide, and 6.5 meters high, weighs 1,100 tons, and was able to produce 11,000 horsepower, or up to 7000 kilowatts. It has four cylinders, each of which had a capacity of 3,000 liters, and an 11-meter and 150-ton flywheel, which rotated at 94 RPM. The engine was operated by 12 workers per shift, and during its lifetime (1942-1979) produced more than 6,000 kW of power from blast furnace gas (a waste product generated by the combustion of coke fuel in blast furnaces).

As in most cases, the size and complexity of the object determines the scanners to be used. Artec Ray was chosen as the primary scanner for capturing the entire engine, due to its ability to scan large objects from a distance with submillimeter accuracy, while the Artec Leo, a wireless, portable 3D scanner, was chosen as a second device, specifically for capturing high levels of detail from the smaller parts and sections of the engine.

While Ray silently scans the engine, Zaremba steps away for a minute or two of scanning smaller sections up close with Leo

The final polygonal 3D model of the Groussgasmaschinn

From 1940s all the way to 2020s, the Groussgasmaschinn got a second breath thanks to the power of 3D scanning technologies

For more, visit Artec 3D's case study.