Have you ever wondered how to preserve and enhance a historic site without compromising its original style and integrity?

That was the challenge our customers faced when they were hired to create new fence panels for Officers’Square, a National Historic Site in Fredericton, Canada.

In this blog post, we will show you how our reseller helped create new ornamantal cast iron fence panels using 3D scanning.

We will also share the benefits of using 3D scanning for this project, such as:

● Saving time and money by avoiding manual measurements and drawings

● Capturing accurate and detailed 3D data of the existing fence panel

● Creating a smooth and symmetrical surface model of the fence panel

● Designing the new top and bottom rail easily and quickly

● Ensuring the fit and quality of the pattern and the casting

If you ever visit Fredericton, the capital city of New Brunswick, Canada, you might want to check out Officers’ Square, a National Historic Site.

The square was once a military base and a public gathering place for the city’s residents. Today, it is a popular spot for cultural events, concerts, and festivals.

The fence of Officers’ Square has undergone several changes over the years. The aim for this project was to create new fence panels that would match the historic style of the original fence, but with a slightly different top rail profile to reflect the new design.

The change is to create a precise 3D model and make sure that the casting model would not replicate 100 years of corrosion and wear, but rather represent the casting fairly.

3D Scanning and Casting for Creating New Fence Panels

Thompson Foundry is a Canadian company that has been manufacturing castings integral to the function and success of a broad range of customers worldwide, for over half a century.

Dependable Industries has been producing high-quality patterns and tooling for a wide variety of industries since 1968. Its family-owned and operated business has an expert staff and highly-experienced pattern makers.

To achieve this, 3D scanning and casting technologies were used.

The 3D scanner they used is KSCAN-Magic portable 3D laser scanner. It is a cutting-edge composite 3D scanner that integrates infrared and blue lasers in one versatile instruments. It boasts five standard operating modes including the ultra-fast 3D scanning and hyperfine scanning.

Step 1: 3D Scanning the Fence Panel

The first step was to 3D scan the existing fence panel using the KSCAN-Magic 2 to capture high-resolution and precise 3D data. The 3D scanner is easy to use and can scan complex objects quickly and accurately.

They 3D scanned the fence panel from different angles and distances, making sure to cover every detail. The 3D scanner automatically aligned the data and created a 3D point cloud of the fence panel.

Step 2: Processing the Data in 3D Design Software

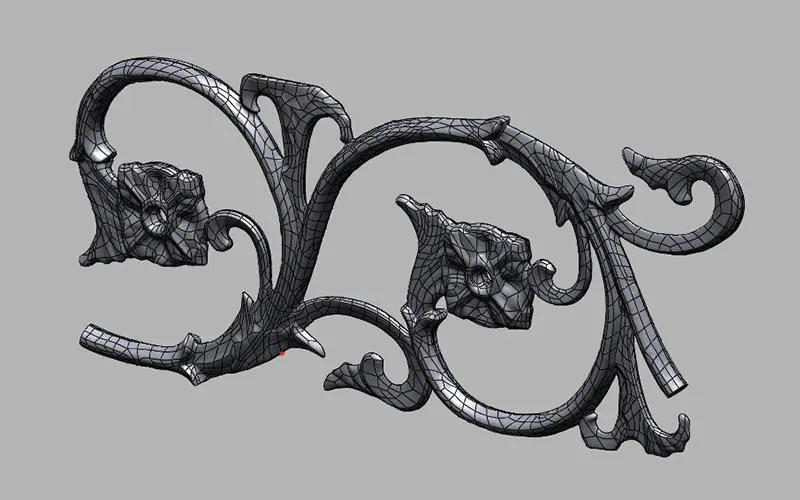

The next step was to import the 3D point cloud data into 3D design software that can convert 3D data into CAD models. Since the 3D scan data was of high quality, they only needed minimal editing and processing to make the CAD model usable.

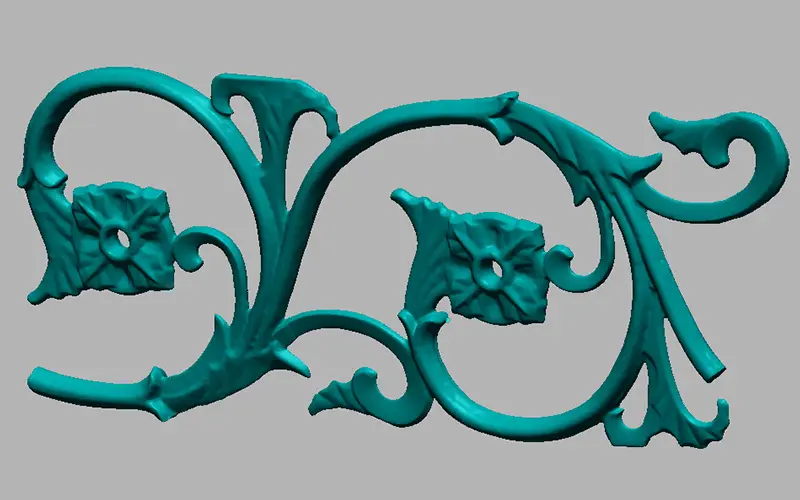

In the software, they removed the top and bottom rail of the fence panel, since they were going to be redesigned. They also used the auto surface feature to generate a smooth surface that captured the details of the fence panel but without the surface irregularities caused by corrosion and wear.

They then split and mirrored the panel to make it symmetrical for pattern manufacturing.

Step 3: Designing the New Top and Bottom Rail

The next step was to design the new top and bottom rail of the fence panel according to the customer’s sketches. They used 3D design software to create the new rail profiles and attach them to the fence panel.

They slightly altered the top rail, while keeping the new rails’ style and dimensions in line with the original fence.

Step 4: Machining the Pattern

The next step was to machine the pattern for the fence panel using Dependable Industries’ CNC machines after the models were arrayed and verified for their fit.

A pattern is a replica of the final product that is used to create a mold for casting. The CAD model of the fence panel was sent to Dependable Industries to machine the pattern.

Step 5: Casting the Fence Panel

The final step was to cast the fence panel using Thompson Foundry’s casting facilities. They used iron as the metal for the fence panel, as it is durable and resistant to corrosion.

After the sand was cast and cleanup, a new fence pane was successfully made.

The Result: New Fence Panels for a Historic Site

The result of the work was a new fence panel that fit perfectly with the historic fence of Officers’ Square. The fence panel had the same style and dimensions as the original fence but with a slightly different top rail profile.

The fence panel also had a smooth and fair surface that did not replicate the corrosion and wear of the old fence.

3D scanning and casting technologies are powerful tools for preserving and enhancing historic sites, as they can capture, replicate, and modify existing structures without compromising their original style and integrity.

These technologies can also save time and money, improve accuracy and quality, and enable creativity and innovation.

The customers were very pleased with the amazing performance and functionality of the 3D scanner KSCAN-Magic. Scantech was honored to provide this precise 3D laser scanners to preserve and enhance the historic site that has a rich history and cultural significance.

We hope that the fence panel will last for many years and be enjoyed by many visitors.

We hope you enjoyed this blog post and learned something new about 3D scanning and casting technologies. If you have a similar project or need 3D scanning for any other purpose, please don’t hesitate to contact us.

info@rapidscan3d.com

(562) 912-3544

Autor Scantech 3D