Rapid Scan 3D is an innovated company that specializes in 3D metrology technology, providing manufactures the best hardware and software for designing and improving products.

Easy Engineering: Which are the fields of activity where you are operating?

Rapid Scan 3D: One of the amazing parts of our business is that we get to work in a lot of different industries including medical, entertainment, automotive and aerospace. Even though many of these applications have different needs, what they have in common is that they have real world objects that they need to bring into 3D. Utilizing our high accuracy 3D scanners allows up to reverse engineer legacy parts for our clients as well as using the data for quality control inspection.

E.E: Which are the most significant projects from 2022?

Rapid Scan 3D: We have had a lot of amazing projects in 2022. Because we work with a lot of big companies, we don’t get to talk about some of the secret projects we worked on. We have worked with the world-famous West Coast Customs & Count Kustoms helping bring in 3D scanning hardware from Artec 3D and Scantech 3D to help build some parts for their custom car builds. There have been a few projects where we have had to 3D scan an old part and redesign it to fit a modern design and create a stronger more efficient part. We continue to have strong partners in the manufacturing industry where obtaining high accuracy data and creating the best possible CAD files.

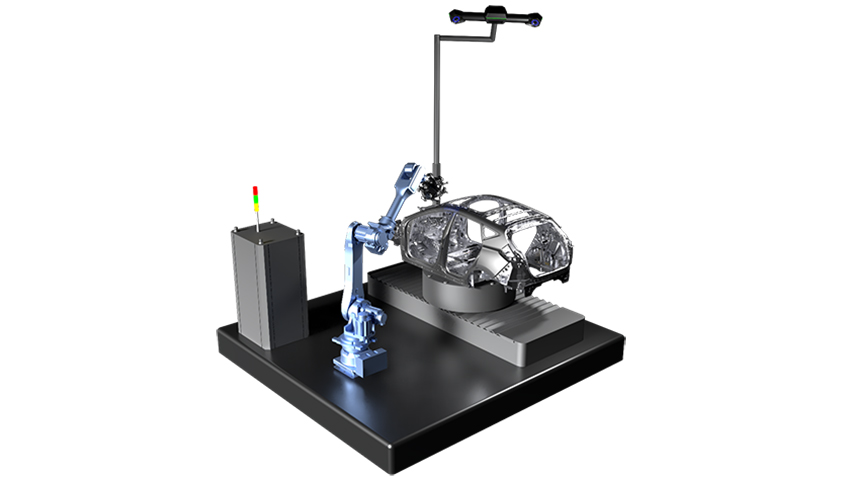

Rapid Scan 3D: Not every 3D scanner will be our client’s needs. This is one of the great things about having a wide range of different systems. The Artec Leo Plus is one of our most innovative 3D scanners. This is the only handheld 3D scanner on market that is fully portable, has no wires and has an onboard computer. The Leo uses camera-based technology to capture data. The scanner doesn’t require targets to align the scans as it can use geometry and texture (color content) to align the scans. What most customer like about the Leo Plus is that it can be used outdoors in the sun, it is accurate and captures full color if needed. We also have a very innovative product from Scantech 3D that have integrated to work with a robotic arm. Our 3D scanning automation station utilizes the Scantech TrackScan P-42, a collaborative robot, granite table and a turntable. This automation allows a tech to automate the scanning process with high repeatability due to the collaborative robot. We use this data for automated inspection with Geomagic Control X software. The data is compared to existing CAD and we can find deviations in parts. The automation continues in Control X software where all measurements are inspected within seconds and can be sent to a PDF report and even sent to upper management with our free viewer. This integration by Rapid Scan 3D provides clients a all-in-one inspection tool that can be implemented in any metrology lab or customer site.

E.E: What was the research behind the products/solutions?

Rapid Scan 3D: Our clients asked, and we answered. The move to automation isn’t the future, it’s happening now. There has been a need to inspect parts from the first day someone designed a part. The old way was using measuring tapes or calipers might work for a quick measurement but 99% of our customers need more. Our clients want a more in depth understanding of their parts and the manufacturing process. This has lead us to integrate collaborate robots with a high end accurate 3D scanner and Geomagic Control X. Our automation solution provides clients with a full inspection solution.