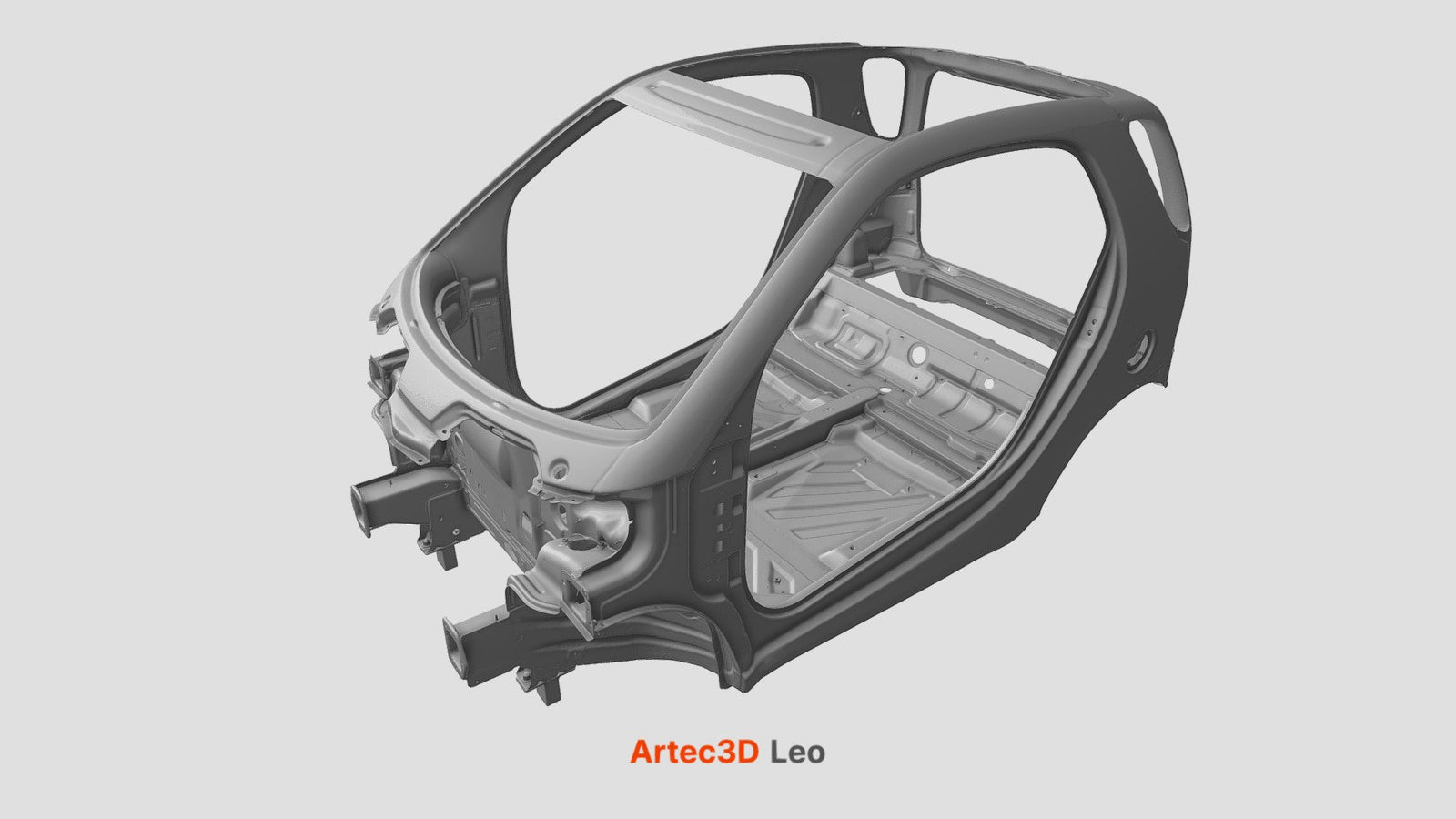

his Smart car frame in sleek 3D is a great example of what the combination of Artec Leo and the Artec Metrology Kit can do when you need to create an ultra-realistic, precise, and accurate 3D model. Complex in size and shape, the car frame is rendered with the smallest parts and most particular details. All smooth and shiny, with numerous intricate in-cuts and curves, this object is a definite challenge for scanning. However, the Leo’s wide scanning range, steady tracking, and impeccable data capture in HD made full digitization entirely possible, with not a detail left unscanned.

With Artec Leo being completely wireless, even the hard-to-reach and thinner areas, such as the side parts, the central front, and particular areas of the upper part and the back, were fully captured. Scanned with the maximum of HD frames, these 5 scans were then reconstructed in an optimal way and in just a couple of hours with Leo’s state-of-the-art algorithms, keeping every edge razor sharp. There was no need to do this for the entire project because simply shooting with Leo provides high quality, crispy-clean scans.

Despite the size of the project, our scanning specialist managed to acquire data from the entire frame in just 1 hour. In addition, Leo is equipped with a size-optimization setting, helping to keep the project as small as possible. To facilitate smoother scanning for upper parts that lacked sufficient features, the team added long strips of paper to the field of view of the scanner. Leo’s portability and a handy tilting screen made it effortless to move around the object for a 360-degree capture, whether diving underneath the frame or climbing into it, all with no cables or wires getting in the way.

When the scanning was done, it was time for the Artec Metrology Kit to take the stage. After some hassle-free preparation that included applying the reference objects and targets placing, all that was left to do was take photographs. Walking around the object, the team took pictures, at different heights, in the same position – this took under 15 minutes. Finally, it was up to Artec Studio to process all the images for another 10 minutes and then work on blending the data into this high-detailed model.

The result: the accurate, detailed, intricate 3D model you see here, all in a day’s work.

If you are an OEM or Aftermarket Automotive comany utilizing 3D scanning can provide an essiential tool for Reverse Engineering and Quality Control Inspection to your workflow. Interested? Contact us for more information and a demonstration.

Want to see a 3D model of the data? https://www.artec3d.com/3d-models/smart-car-frame?utm_source=linkedin.com&utm_medium=social&utm_campaign=organic_post